Professional Manufacturer of Biomagnetic Beads

What The Differences Between Monodisperse Polystyrene Magnetic Beads and Polydisperse Silica Magnetic Beads?

Monodisperse polystyrene (PS) magnetic beads and polydisperse silica (SiO₂) magnetic beads exhibit significant differences in material properties, size distribution, surface modification, and applications. Below is a detailed comparison:

1. Material Properties and Structure

| Property | Monodisperse Polystyrene Beads | Polydisperse Silica Beads |

| Core Material | Polystyrene (organic polymer) | Silica (inorganic) |

| Magnetic Component | Embedded Fe₃O₄ nanoparticles | Surface-coated/doped Fe₃O₄ |

| Structural Stability | High flexibility, low shear resistance | High rigidity, heat/pressure resistant |

| Density (g/cm³) | 1.05–1.2 (near-aqueous) | 1.8–2.2 (prone to sedimentation) |

2. Size Distribution

| Parameter | Monodisperse Polystyrene Beads |

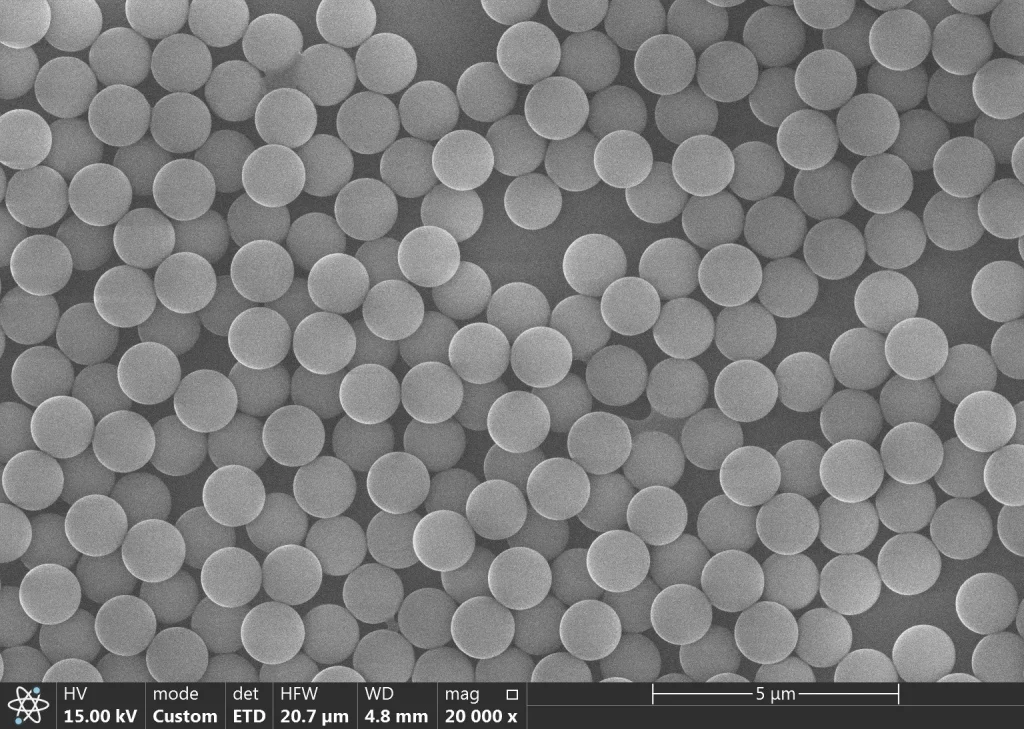

| Size Range | Monodisperse (CV <5%), e.g., 1 μm ±0.05 μm |

| Uniformity Impact | High batch consistency, ideal for automation |

| Surface Area Ratio | Low (uniform size) |

Figure 1:Monodisperse polystyrene magnetic beads in SEM

3. Surface Modification and Functionalization

| Property | Polystyrene Beads | Silica Beads |

| Active Groups | Carboxyl (-COOH), amino (-NH₂), streptavidin | Silanol (-SiOH), modifiable to amino/epoxy groups |

| Modification Complexity | Easy organic functionalization (antibodies/probes) | Requires silanization, complex steps |

| Non-specific Adsorption | Higher (hydrophobic surface) | Lower (hydrophilic surface) |

4. Application Scenarios

| Application | Polystyrene Bead Advantages | Silica Bead Advantages |

| Nucleic Acid Extraction | Ideal for automated high-throughput systems (uniform magnetic response) | Low-cost, suitable for manual operations |

| Immunoassays | Easy antibody conjugation (ELISA/chemiluminescence) | Low background noise, unstable conjugation |

| Cell Sorting | Biocompatible, minimal cell damage | Rigid surface may trigger cell stress |

| Drug Carriers | Controlled release (flexible structure) | High loading capacity (porous structure) |

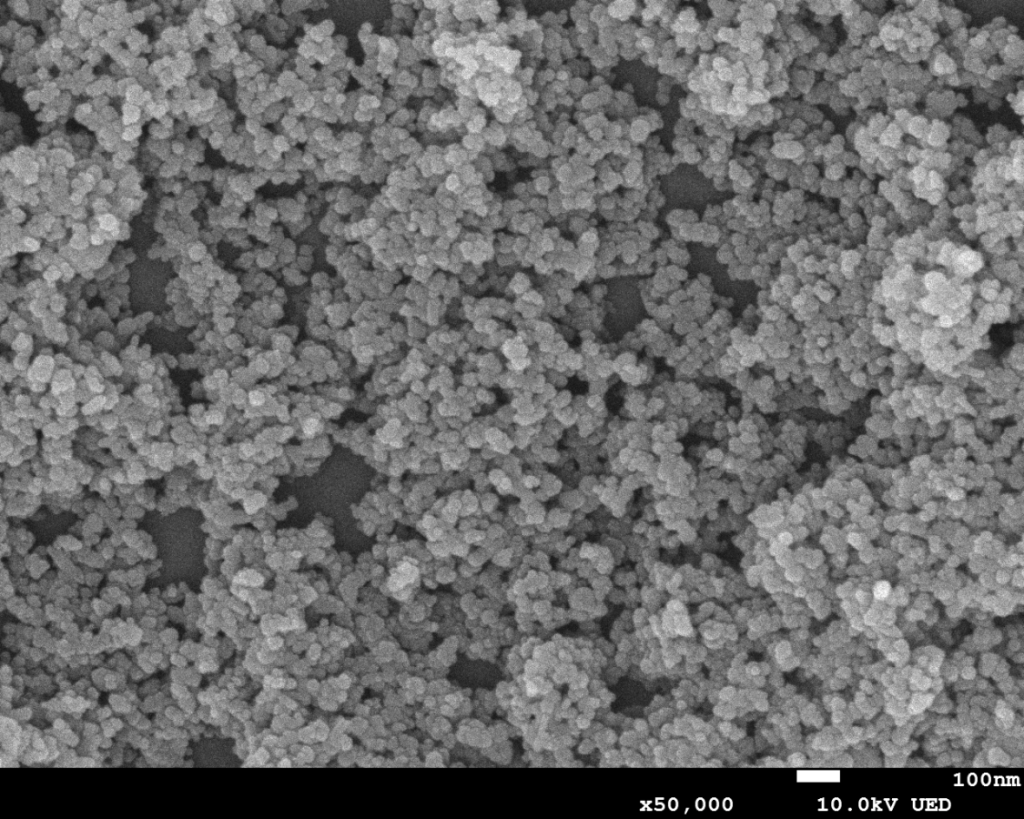

Figure 2:polydisperse silica magnetic beads in SEM

5. Limitations

Polystyrene Beads:

Low density → slow magnetic response (longer separation time);Deformation at high temperatures (<80°C limit);Swelling in organic solvents (e.g., DMSO, acetonitrile).

Silica Beads:

Polydispersity → poor batch reproducibility;

Dissolution in strong alkali (pH >9);

Silanol groups induce aggregation via hydrogen bonding.

Typical Use Cases

Polystyrene Beads:

Automated nucleic acid extraction systems (e.g., KingFisher) with precise 1 μm bead handling;

Fluorescently encoded beads for flow cytometry (CV <3% ensures signal uniformity).

Silica Beads:

Low-cost nucleic acid kits (e.g., LNJNBio Magnetic Method Nucleic Acid Extraction Kit);

Industrial enzyme immobilization (high surface area for protein loading).

Selection Guidelines

High-throughput/Automation: Choose polystyrene beads (size uniformity ensures process stability);

Cost-sensitive/Manual Operations: Opt for silica beads (pre-screen to minimize size variability);

Harsh Conditions (heat/organic solvents): Prefer silica beads (superior chemical resistance).

Emerging Trend: Composite beads (e.g., SiO₂@PS core-shell) combine advantages, featuring a rigid core and modifiable organic surface, gaining traction in high-precision diagnostics.

Supplier

Shanghai Lingjun Biotechnology Co., Ltd. was established in 2016 which is a professional manufacturer of biomagnetic materials and nucleic acid extraction reagents.

We have rich experience in nucleic acid extraction and purification, protein purification, cell separation, chemiluminescence, and other technical fields.

Our products are widely used in many fields, such as medical testing, genetic testing, university research, genetic breeding, and so on. We not only provide products but also can undertake OEM, ODM, and other needs. If you have a related need, please feel free to contact us .