Professional Manufacturer of Biomagnetic Beads

Pure Water in Three Steps: Rapid Treatment with Magnetic Beads

Dear friends in environmental protection and water treatment,Have you ever been overwhelmed by the challenges of treating complex industrial wastewater? Heavy metalbe over the accepted norm, stubborn organic pollutants, high sludge disposal costs… Worry no more! Today, we introduce a technology that is both highly effective and low-maintenance — the Silica-Based Magnetic Beads Wastewater Treatment Solution! No sorcery, just science — transforming polluted water into clear streams effortlessly!

1. Three Major Application Scenarios & Practical Solutions

Scenario 1: Removal of Heavy Metals from Electroplating Wastewater

Issue: Excessive Ni²⁺, Cr⁶⁺; slow sedimentation and high sludge volume in traditional processes

Solution:Add amino-modified silica-based magnetic beads (-NH₂ specifically captures heavy metals)

Magnetic separation (solid-liquid separation completed in 5 minutes)

Acid washing regeneration (recovering heavy metal resources, beads recycled)

Data speaks:

Nickel removal rate > 95%,Sludge reduction by 70%

Annual metal recovery value up to $ 70,183.32 per 10,000 tons of water

Scenario 2: Treatment of Oily Wastewater in Petrochemical Industry

Issue: Difficult separation of emulsified oils; high cost of chemical demulsification

Solution: Use hydrophobically modified beads (C18 alkyl chain modification)

Beads bind with oil droplets to form “magnetized oil clusters”

Magnetic recovery (oil removal rate > 90%)

Advantages:

No demulsifier needed, reducing costs by 40%

Treatment time shortened from 2 hours to 10 minutes

Scenario 3 Advanced Phosphorus Removal in Municipal Wastewater

Issue: Phosphorus pollution causes eutrophication

Solution: Zirconium-loaded magnetic beads (Zr@SiO₂@Fe₃O₄)

Specific adsorption of phosphates

Alkaline washing regeneration for reuse

Results:

Phosphorus adsorption capacity > 45 mg/g

Effluent total phosphorus < 0.3 mg/L (meeting Surface Water Class III standards)

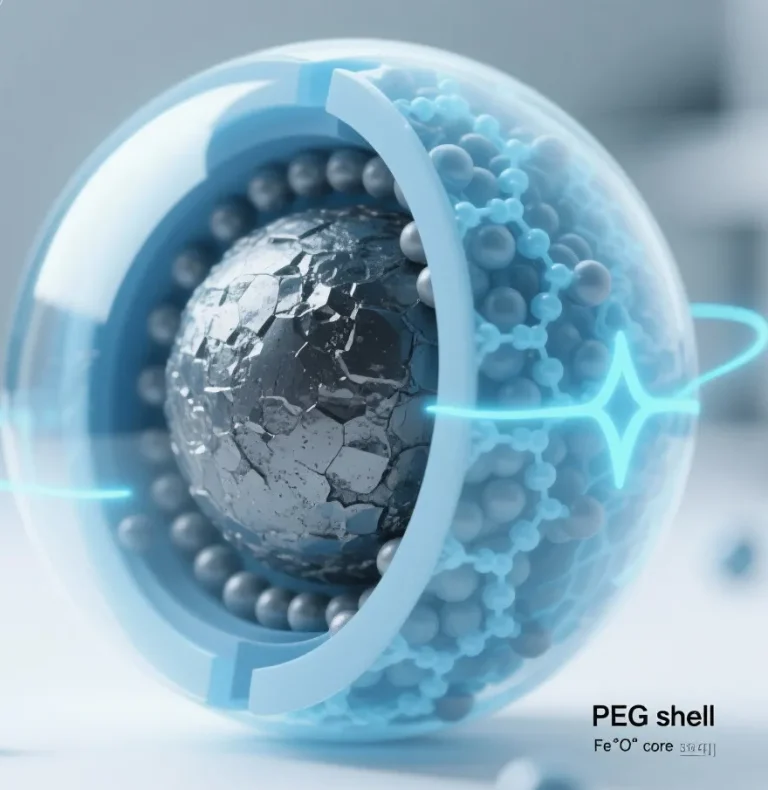

2. Unveiling the Technical Mechanism!

“Magnetic Hunter” Adsorption Mechanism:

Electrostatic adsorption (charged groups like -OH, -NH₂ capture ions)

Chemical coordination (heavy metals form stable complexes with functional groups)

Hydrophobic interaction (alkyl chains efficiently capture organic pollutants)

“Second-Level Separation” Magnetic Response:

Under an external magnetic field, magnetic beads aggregate within 10 seconds — no need for lengthy sedimentation or filtration.

“Regeneration Master” Cycling Design:

Acid regeneration (0.1M HNO₃ desorbs heavy metals)

Thermal regeneration (300°C calcination decomposes organics)

After 10 cycles, adsorption capacity remains > 85%

3. Dimensional Advantage Over Traditional Processes!

| Metric | Silica-Based Magnetic Beads | Traditional Activated Carbon |

| Adsorption Capacity | 300 mg/g (for Pb²⁺) | 150 mg/g |

| Separation Time | < 5 minutes | 2-4 hours |

| Reuse Cycles | ≥ 10 times | 3-5 times |

| Sludge Production | Reduced by 70% | Large volume, difficult disposal |

| Automation Level | Fully automated | Manual operation required |

Let’s empower your wastewater treatment with magnetic technology — add an “accelerator” to your wastewater treatment process!

Place your order now—don’t hesitate!

Supplier

Shanghai Lingjun Biotechnology Co., Ltd. was established in 2016 which is a professional manufacturer of biomagnetic materials and nucleic acid extraction reagents.

We have rich experience in nucleic acid extraction and purification, protein purification, cell separation, chemiluminescence, and other technical fields.

Our products are widely used in many fields, such as medical testing, genetic testing, university research, genetic breeding, and so on. We not only provide products but also can undertake OEM, ODM, and other needs. If you have a related need, please feel free to contact us .