Professional Manufacturer of Biomagnetic Beads

PEG-Fe3O4: The Nano-Engine Revolutionizing Magnetic Fluid Sealing Performance

Preface

In the relentless pursuit of ultimate reliability and zero leakage rates within the industrial sealing sector, PEG-Fe3O4 nanoparticles, are emerging as the core material for a new generation of high-performance magnetic fluids, providing cutting-edge solutions for sealing challenges under harsh operating conditions. The overall efficacy of magnetic fluid sealing technology fundamentally depends on the comprehensive performance of its core component – the magnetic nanoparticles.

Confronting common technical challenges of traditional magnetic fluids, such as particle agglomeration, insufficient long-term stability, and limited compatibility with working media, PEG-Fe3O4 nanoparticles successfully break through these bottlenecks via their unique surface chemistry design and structural control, pushing the performance boundaries of magnetic fluid sealing to new heights.

1. Sealing Principle: How PEG Modification Empowers Fe3O4 Nanoparticles

The application of PEG-Fe3O4 in magnetic fluid sealing is based on a sophisticated synergistic effect at the nanoscale.

1.1. Superparamagnetic Core

The core PEG-Fe3O4 nanoparticles exhibit perfect superparamagnetic characteristics. Under an external magnetic field, the particles can generate strong magnetization, ensuring a robust sealing structure. Upon removal of the magnetic field, their remanent magnetization is nearly zero, effectively preventing magnetic agglomeration between particles and guaranteeing smooth flow and redispersibility of the magnetic fluid.

1.2 PEG “Smart Shell”

The PEG molecular layer coating the surface of the Fe3O4 particles plays multiple crucial roles:

- Steric Hindrance Stabilization: PEG long molecular chains form a flexible “hydration shell” on the particle surface. Through powerful steric hindrance effects, it effectively inhibits the spontaneous aggregation of nanoparticles caused by van der Waals forces, ensuring their long-term, stable dispersion in the carrier liquid.

- Enhanced Interfacial Compatibility: As an amphiphilic polymer, PEG can significantly improve the compatibility of the magnetic fluid with various working media (including specialty lubricants and industrial chemicals), reducing performance degradation due to interfacial incompatibility.

- Protective Barrier Function: The PEG layer can, to some extent, isolate the core Fe3O4 from direct contact with harsh external environments (e.g., weakly acidic or alkaline media), enhancing the overall corrosion resistance and long-term operational stability of the magnetic fluid system.

- Based on this mechanism, when the PEG-Fe3O4 magnetic fluid is injected into the gradient magnetic field formed by permanent magnets and pole pieces, these highly stable and rapidly magnetically responsive nanoparticles can instantly form a uniform, dense liquid sealing ring, enabling highly efficient dynamic sealing during rotational or reciprocating motion.

2. Core Advantages: Why Choose PEG-Fe3O4-Based Magnetic Fluids

Compared to traditional magnetic fluids, the technical advantages offered by PEG-Fe3O4 materials are significant:

- Exceptional Stability and Service Life: The steric hindrance stabilization mechanism provided by PEG fundamentally addresses the issues of nanoparticle settlement and agglomeration. This substantially extends the performance lifespan of the sealing fluid, achieving a continuous service life increase of over 20% compared to traditional products under typical operating conditions, significantly reducing equipment maintenance frequency and lifecycle costs.

- Extremely Low Leakage Rate Performance: Benefiting from the dense sealing barrier formed by monodisperse nanoparticles, PEG-Fe3O4 magnetic fluid can easily achieve ultra-high vacuum sealing performance on the order of < 1×10⁻¹² Pa·m³/s, meeting the extreme requirements for vacuum sealing in cutting-edge industries like semiconductors and photovoltaics.

- Broader Operating Condition Range: PEG modification effectively enhances the magnetic fluid’s tolerance to temperature fluctuations and chemical environments. Our PEG-Fe3O4 maintains stable performance across a wide temperature range of -40°C to 120°C and adapts to various non-strongly corrosive industrial atmospheres.

- Excellent Tribological Properties and Energy Efficiency: The inherent superparamagnetism of the material ensures almost no magnetic residue after the magnetic field is removed, guaranteeing very low flow resistance and shear stress. Its frictional torque is significantly lower than that of mechanical seals, contributing to energy-efficient operation of equipment.

3. Main Application Fields

The outstanding characteristics of PEG-Fe3O4-based magnetic fluid seals make them a key technological choice in several high-end industrial fields:

- Semiconductor and Photovoltaic Manufacturing: Provides oil-free, clean, ultra-high vacuum sealing environments for transmission shaft seals in monocrystalline silicon growth furnaces, vacuum coating equipment, and ion implanters, offering solid assurance for the manufacturing yield of chips and photovoltaic panels.

- High-End Analytical Instruments: Used in rotating introduction systems for sample chambers or electron guns of precision instruments like mass spectrometers and electron microscopes, ensuring instruments maintain high vacuum over the long term and guaranteeing the accuracy of test data and instrument stability.

- Specialty Chemical and Energy Equipment: Provides reliable dynamic sealing solutions for critical parts such as transfer pumps for special gases or chemical media and reactor stirrer shafts, effectively preventing the leakage of hazardous substances and ensuring production safety and environmental protection.

- Aerospace Field: Serves as a long-life, highly reliable sealing solution for key components like satellite attitude control flywheels and space experiment equipment, providing technical support for the stable on-orbit operation of spacecraft.

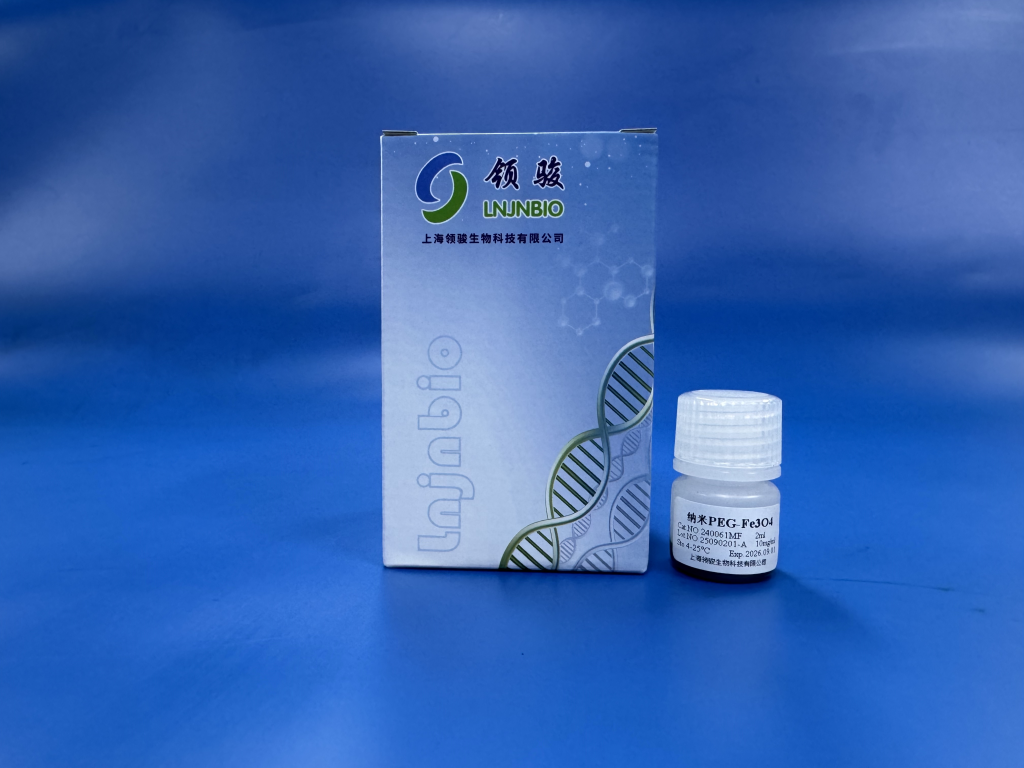

4. Product Introduction

Shanghai Lingjun has successfully prepared high-performance PEG-Fe3O4 nanomaterials through its independently developed process. This product combines the superparamagnetism of PEG-Fe3O4 with the high hydrophilicity, biocompatibility, and anti-protein adsorption properties of PEG, exhibiting excellent colloidal stability and long circulation lifetime. While maintaining its potential for biomedical applications, this product has been specifically optimized and functionally enhanced for industrial magnetic fluid sealing scenarios.

Our product offers the following core advantages:

- Superparamagnetism: Possesses strong magnetic responsiveness, no remanence, facilitating rapid magnetic separation and precise control.

- Excellent Stability: Disperses uniformly in aqueous phases and various buffer systems, strong resistance to aggregation, adaptable to complex working conditions.

- Surface Functionalizability: Supports further coupling with specific targeting molecules or functional groups for performance customization.

- Good Batch Consistency: Stable preparation process, high product reproducibility, meeting industrial application requirements.

Shanghai Lingjun is committed to driving the innovation process of industrial sealing technology together with industry partners through professional nanomaterial solutions, tackling future technical challenges.

Supplier

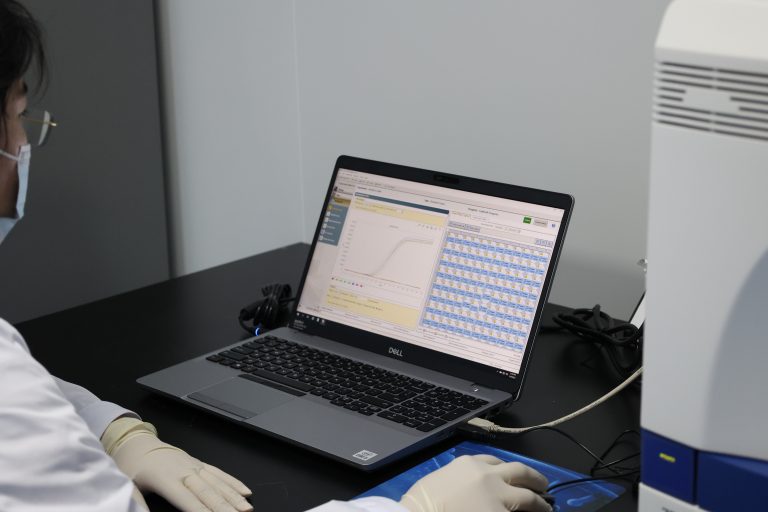

Shanghai Lingjun Biotechnology Co., Ltd. was established in 2016 which is a professional manufacturer of biomagnetic materials and nucleic acid extraction reagents.

We have rich experience in nucleic acid extraction and purification, protein purification, cell separation, chemiluminescence, and other technical fields.

Our products are widely used in many fields, such as medical testing, genetic testing, university research, genetic breeding, and so on. We not only provide products but also can undertake OEM, ODM, and other needs. If you have a related need, please feel free to contact us .