Professional Manufacturer of Biomagnetic Beads

Magnetic Fluid Sealing: A Key Technology for Advanced Automotive Systems

Foreword

On the path of pursuing high performance and high reliability in the automotive industry, a magnetic fluid sealing technology originating from the aerospace field is quietly reshaping the sealing standards for key automotive components. Leveraging its proven exceptional performance in high-end industrial sectors like semiconductors and vacuum coating, this technology is carving out a broad application landscape within the automotive industry.

Magnetic fluid sealing technology breaks through the solid contact limitations of traditional mechanical seals, achieving non-contact dynamic sealing between moving parts. It fundamentally solves problems faced by traditional sealing technologies, such as wear, leakage, and short service life, injecting new momentum into enhancing vehicle performance and reliability.

1. Technical Principle: The Outstanding Characteristics of Magnetic Fluid Sealing

Magnetic fluid sealing is an innovative technology based on the properties of nano-magnetic materials. Its core is a stable suspension system composed of ferromagnetic nanoparticles, a carrier liquid, and surfactants. Under the action of a gradient magnetic field, the magnetic fluid can form a liquid sealing barrier in the gaps between moving components, achieving dynamic sealing with zero wear.This technology offers the following prominent features:

- Extremely Low Leakage Rate: Achieves levels < 1×10⁻¹² Pa·m³/s

- Ultra-Long Service Life: Continuous operation can reach over 20,000 hours

- Low Friction Loss: Frictional torque is only 1/10 that of traditional seals

- Wide Temperature Range Adaptability: Maintains stable performance within -40℃ to 120℃

2. Application Scenarios: Sealing Innovation in Key Automotive Components

2.1 Engine System: Enhancing Efficiency and Reliability

Magnetic fluid sealing technology shows great potential in the internal combustion engine (ICE) field. Innovative magnetic fluid sealing structures for ICE cylinders and pistons use multi-stage magnet assemblies to generate strong magnetic fields that fix the magnetic fluid, replacing traditional piston rings. This design not only provides excellent sealing performance but also offers lubrication functions, potentially significantly increasing engine power by approximately 20%, while eliminating the need for periodic overhauls.

For high-speed rotating shaft seals, high-speed and heavy-duty magnetic fluid sealing devices ensure stability between the housing and the shaft through dual magnetic fluid sealing mechanisms, making them particularly suitable for high-speed operating components like automotive transmission systems.

2.2 Shock Absorber System: Comprehensive Sealing Performance Enhancement

Magnetic fluid sealing technology has successfully solved issues in automotive shock absorbers such as rapid heat generation in traditional guide seals, lack of bidirectional sealing capability, and high oil leakage rates. Metallic magnetic fluid guide sealing devices, through precise gap control and multi-stage sealing structures, achieve low friction and bidirectional sealing capability across high and low temperatures, significantly reducing internal leakage and operating noise in shock absorbers.

2.3 Engine Mount System: Innovative Application of Intelligent Damping

The German Porsche GT3 model pioneered the use of a magnetic fluid-based engine mount. By adjusting the coil current in real-time to change the fluid viscosity, it achieves intelligent damping control. The system precisely controls the current based on parameters like throttle opening, vehicle speed, and engine RPM, effectively reducing drivetrain vibrations, lowering noise, and enhancing vehicle dynamic characteristics.

3. Application Status: Technology Implementation and Industrial Progress

Currently, magnetic fluid sealing technology has achieved substantial application in several areas of the automotive industry:

- Pioneering Adoption by Premium Brands: Brands like Porsche have already applied magnetic fluid sealing technology in engine mount systems.

- Accelerating Localization Process: Domestic companies have successfully developed high-speed and heavy-duty magnetic fluid sealing devices.

- Key Technological Breakthroughs: Metallic magnetic fluid guide sealing technology has achieved industrial application in the shock absorber field.

- Significant Efficiency Improvements: ICE applications demonstrate the technical potential to increase engine power by 20%.

4. Future Outlook: Technology Development Trends

With the rapid development of the automotive industry towards electrification and intelligence, magnetic fluid sealing technology will encounter broader application prospects:

4.1 Sealing for Key Electric Vehicle Components

In EV motors, battery cooling systems, and electronic control systems, magnetic fluid seals can provide an oil-free, clean sealing environment for high-speed rotating components, meeting the stringent requirements of electric vehicles for high reliability and long life.

4.2 Intelligent Suspension Systems

Combined with magnetorheological (MR) fluid technology, magnetic fluid sealing can contribute to the development of more intelligent and responsive suspension systems, significantly improving vehicle handling and comfort.

4.3 Integration and Standardization Development

As automotive components trend towards integration and modularization, magnetic fluid seals can be embedded as standard sealing modules into various key components, simplifying design and manufacturing processes.

4.4 Material Innovation Drives Performance Breakthroughs

The development of new magnetic fluid materials, particularly nano-composite magnetic fluids with high sedimentation resistance and wide temperature range stability, will further enhance the adaptability of magnetic fluid seals to extreme operating conditions and their service life.

5. Product Advantages: Shanghai Lingjun Magnetic Fluid

The magnetic fluid developed by Shanghai Lingjun through proprietary process technology possesses excellent anti-sedimentation performance and superparamagnetism, providing professional solutions for the automotive sealing field.

Our Core Advantages:

- Exceptional Magnetic Properties: Strong magnetic responsiveness, no remanence, enabling fast and precise control.

- Extremely High Stability: Maintains uniform dispersion under complex working conditions, strong resistance to aggregation.

- Wide Temperature Range Adaptability: Stable performance within -40°C to 120°C.

- Long-Lasting Durability: Excellent anti-sedimentation performance, significantly enhanced service life.

- Batch Consistency: Stable and reliable process, high product reproducibility.

As an important direction for automotive industry technological upgrades, magnetic fluid sealing technology, with its excellent sealing performance, long life, and intelligent controllability, is providing reliable sealing solutions for key automotive components. From engines to shock absorbers, from transmission systems to intelligent suspensions, the expanding application of this technology will inevitably drive the automotive industry towards higher performance, greater reliability, and increased intelligence.

Shanghai Lingjun is dedicated to the innovation and application of magnetic fluid sealing technology. We are willing to join hands with industry partners, through our advanced magnetic fluid products and professional technical services, to jointly promote the technological progress and industrial upgrading of China’s automotive industry, contributing to the development of the global automotive manufacturing industry.

Supplier

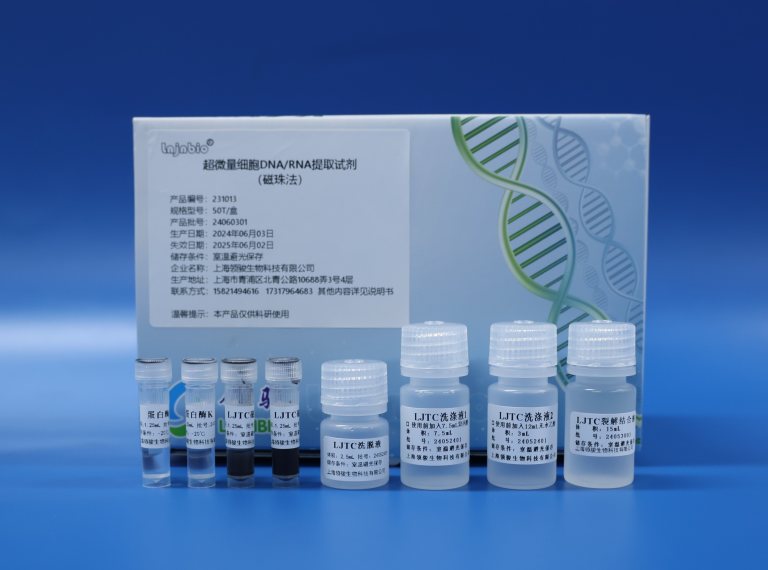

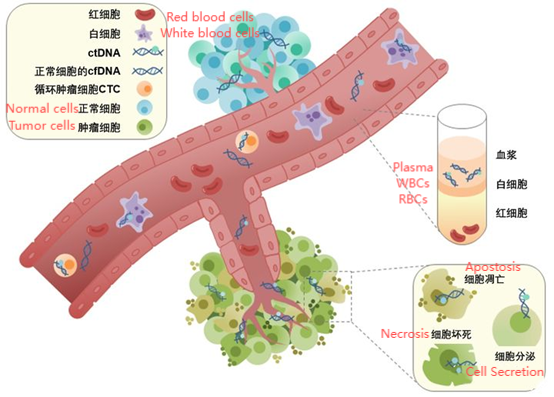

Shanghai Lingjun Biotechnology Co., Ltd. was established in 2016 which is a professional manufacturer of biomagnetic materials and nucleic acid extraction reagents.

We have rich experience in nucleic acid extraction and purification, protein purification, cell separation, chemiluminescence, and other technical fields.

Our products are widely used in many fields, such as medical testing, genetic testing, university research, genetic breeding, and so on. We not only provide products but also can undertake OEM, ODM, and other needs. If you have a related need, please feel free to contact us .