Professional Manufacturer of Biomagnetic Beads

The magnetic properties of magnetic nanoparticles make them easy to enrich and separate or orient for mobile positioning. This property makes magnetic nanoparticles widely used in biological separation and purification techniques. However, the large specific surface area and high surface energy of magnetic nanoparticles make them very susceptible to aggregation, thus affecting their application.

I. Methods and mechanisms to improve the dispersion stability of magnetic nanoparticles

There are two methods of dispersion of magnetic nanoparticles, physical dispersion methods and chemical dispersion methods.

1. Physical Dispersion Methods: Mechanical stirring dispersion, ultrasonic dispersion and impact stream dispersion.

Mechanical dispersion: It refers to the use of strong mechanical stirring to cause strong turbulence in the liquid flow to make particles dispersed in the medium, mainly through the mechanical force applied to the dispersion system, which causes changes in the physical and chemical properties of the substances in the system as well as a series of accompanying chemical reactions to achieve the purpose of dispersion. Mechanical stirring dispersion mainly includes ball milling dispersion, sand milling dispersion, and mechanical high-speed stirring dispersion.

Ultrasonic: It is an effective method to disperse nanoparticles. It means that under the action of ultrasonic waves, the microbubbles in the liquid will rapidly nucleate, grow and vibrate. When the acoustic pressure is large enough, the bubbles will violently collapse. When the bubbles collapse, they will produce high-speed micro-jets and shock waves. At the same time, in a very short time, in the tiny space around the air bubbles, they will produce high temperatures of up to more than 5000K and high pressures of up to 100MPa. These constitute a special environment where the substances will undergo chemical and physical changes. environment. When this effect occurs on a solid surface, due to the liquid around the particles of the strong mixing effect, it accelerates heat conduction and material transfer process and even promotes the diffusion of substances in the solid space. Using this effect, the interaction energy between nanoparticles can be weakened substantially, thus effectively preventing nanoparticles from agglomerating and allowing them to be fully dispersed.

Impact stream dispersion: It refers to the two streams of fluid along the axis of high-speed phase collision. Jet impingement process on the crushing and dispersing process produce two important roles: First, between phases and particles of the collision, mutual abrasion generated by the impact pressure and shear caused by the fragmentation of particles; Second, the collision of the continuous phase of the phase of the phase of the flow, i.e., the jets hit each other to produce a strong radial and axial turbulence velocity component, thus creating a good mixing in the impingement zone.

2. Chemical dispersion methods: mainly including surface modification and adding dispersants.

Surface modification: A layer of organic or inorganic substances coated on the surface of particles can change the surface properties of particles to improve the dispersion stability of particles. Surface coating modification mainly has the following kinds: precipitation modification, heterogeneous flocculation method and surface graft modification method. Precipitation modification is a method of modifying nanoparticles with inorganic coating, which uses a chemical reaction and deposits its product on the surface of the modified powder to form a very thin layer of encapsulated modified layer, thus reducing the activity of nanoparticles and improving their dispersibility. Heterogeneous flocculation uses the electrostatic attraction of government-charged particles to form neutral aggregates and deposit them into an encapsulated layer. Surface grafting modification is to make organic functional groups cover the surface of nanoparticles by chemisorption or chemical reaction, so as to improve the dispersibility of nanoparticles. After surface grafting of nanoparticles, they do not have good long-term dispersion stability in any solvent, and the polymer involved in grafting must be compatible with the corresponding solvent in order to achieve stable dispersion.

Addition of dispersants: When preparing or using magnetic nanoparticles, some dispersion stabilizers, such as surfactants, can be added. These stabilizers can be adsorbed on the surface of the particles to prevent particle aggregation. Commonly used dispersants are inorganic electrolytes, polymers, and polymer polyelectrolytes. Inorganic electrolytes are mainly used for the dispersion of polar surface particles in water. Inorganic electrolytes can increase the absolute value of the surface potential of the particles and improve the electrostatic repulsion of the double electric layer between the particles, such as sodium hexametaphosphate. Polymer with high molecular weight is adsorbed on the surface of particles, and its long polymer chain stretches in the medium, which improves the stability of particle dispersion by spatial site resistance effect. The stability of the dispersion system increases with the thickness of the polymer adsorption layer. For the selected polymer, water should be a good solvent so that the nematic polymer actives can be fully unfolded to obtain a thicker adsorption layer. When polymer polyelectrolyte is adsorbed on the particle surface, it dissociates and carries charge under a certain PH value, which increases the charge on the particle surface and improves the electrostatic repulsive energy on the particle surface, and at the same time, the polymer chain can also play a role in spatial site resistance, such as polyacrylamide. However, when using polymer polyelectrolyte as a dispersant, attention should be paid to the adjustment of PH value so that the dissociation degree of polyelectrolyte is maximum so that the polyelectrolyte on the particle surface reaches saturation adsorption, increasing the double layer repulsion.

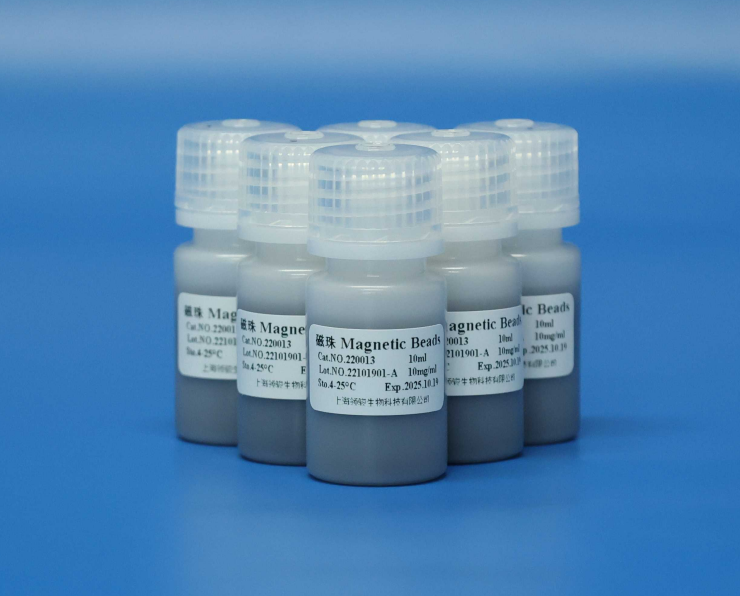

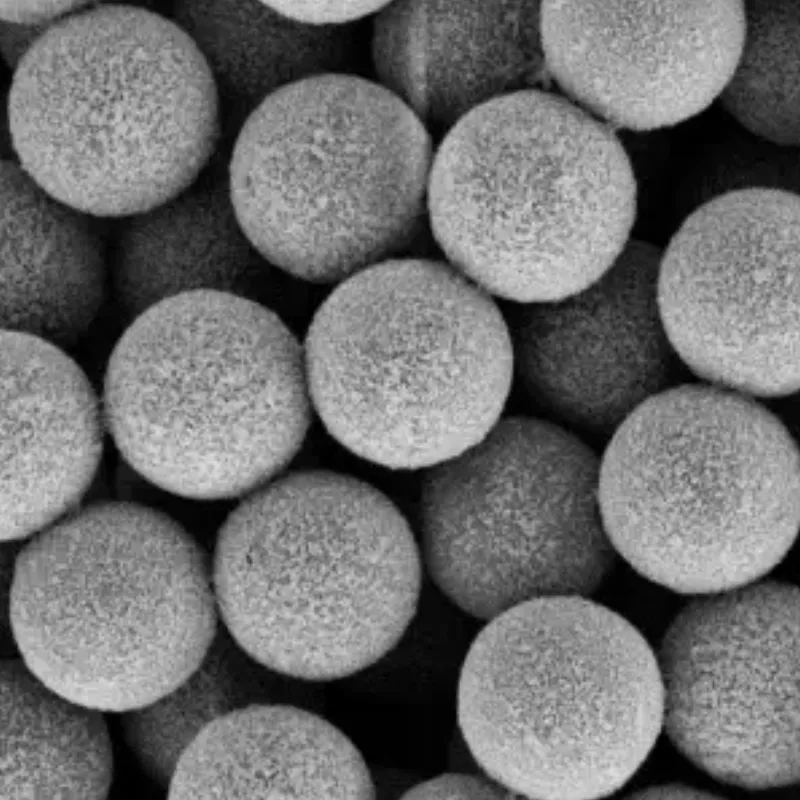

II. Our highly dispersible magnetic particles

We have obtained highly dispersible hydrophilic magnetic fluid by modifying magnetic nanoparticles with our unique technology, which has good dispersion uniformity, no remanent magnetism, strong magnetism, and a variety of particle sizes to choose from. Welcome to consult and communicate with us!

Shanghai Lingjun Biotechnology Co., Ltd. was established in 2016 which is a professional manufacturer of biomagnetic materials and nucleic acid extraction reagents.

We have rich experience in nucleic acid extraction and purification, protein purification, cell separation, chemiluminescence and other technical fields.

Our products are widely used in many fields, such as medical testing, genetic testing, university research, genetic breeding, and so on. We not only provide products but also can undertake OEM, ODM, and other needs. If you have related needs, please feel free to contact us at sales01@lingjunbio.com.