Professional Manufacturer of Biomagnetic Beads

The Transformative Impact of Magnetic Fluids on Industry

1 Prologue

A seemingly ordinary black liquid is quietly changing production methods across numerous industries. It is the protagonist we introduce today—magnetic fluid.

In today’s rapidly advancing technological landscape, a remarkable substance known as magnetic fluid—possessing both the flow properties of a liquid and the characteristics of magnetic materials—is gradually capturing attention. It exhibits unique properties and demonstrates immense application potential across various fields.

Whether it is cooling electronic devices, improving medical equipment, or optimizing new energy systems, magnetic fluid technology is leading a new industrial transformation with its outstanding performance.

2 What Is Magnetic Fluid?

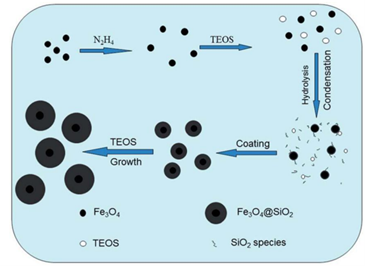

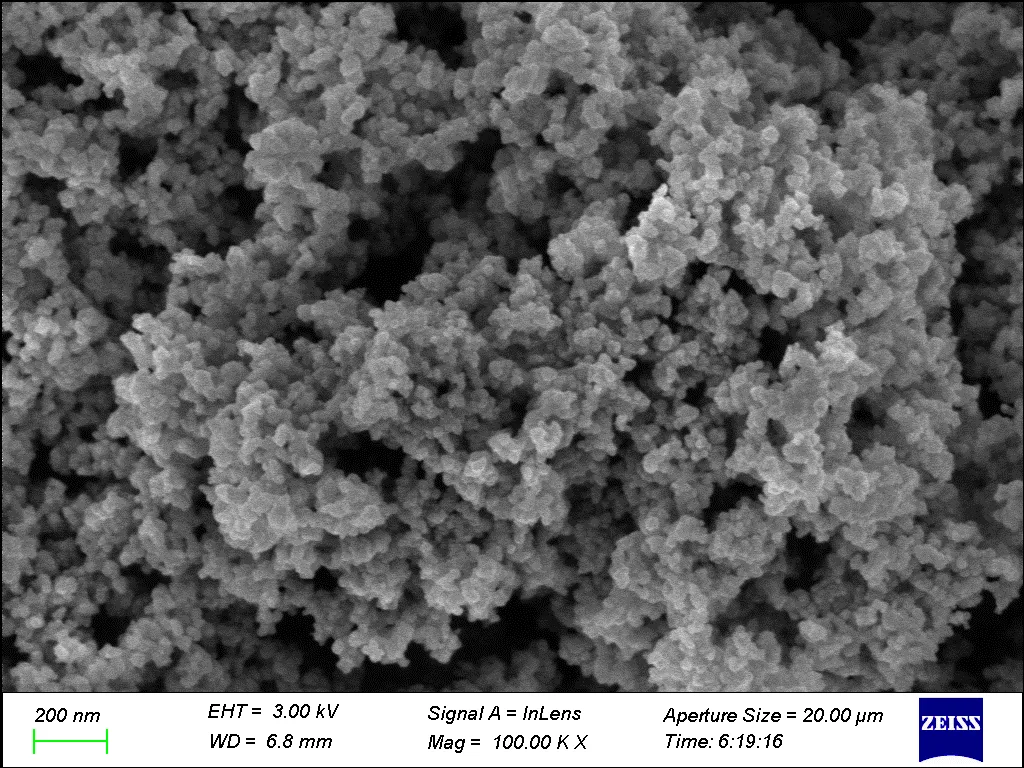

Magnetic fluid is a stable colloid composed of nanoscale magnetic particles, surfactants, and a base liquid. This fluid possesses both the flowability of a liquid and the properties of magnetic materials.

Most remarkably, magnetic fluid can alter its form and flow characteristics under the influence of an external magnetic field, even maintaining exceptional stability under various conditions.

3 Thermal Management: A Revolutionary Breakthrough in Cooling Technology

3.1 In the field of electronic devices, heat dissipation has always been a bottleneck limiting device performance and lifespan. Traditional cooling technologies, such as fans or liquid cooling pumps, often generate significant noise during operation.

ZTE Corporation has already applied for a patent on a “magnetic fluid cooling device and electronic equipment.” This technology utilizes the flow of magnetic fluid under a magnetic field to achieve heat dissipation.

The magnetic fluid cooling device primarily consists of a sealed chamber and a magnetic drive component. The sealed chamber’s cavity is filled with magnetic fluid, and its outer wall contacts the heat source.

3.2 The magnetic drive component generates a varying magnetic field, causing the magnetic fluid within the sealed chamber to flow under its influence. This flow carries the absorbed heat to the sidewalls of the sealed chamber, where it is dissipated to the external environment.

Since the magnetic drive component does not come into contact with the magnetic fluid inside the sealed chamber, it does not generate noise caused by physical contact. Thus, it avoids the issue of excessive noise during the operation of fans or liquid cooling pumps.

4 Energy and Power: A New Solution for Enhancing Equipment Efficiency and Reliability

4.1 In the energy and power sector, magnetic fluid technology also demonstrates significant value. China Yangtze Power Co., Ltd. has filed a patent for a “dual-magnetic-source magnetic fluid sealing device and cooling control system.”

This patented technology enhances the device’s magnetic flux aggregation capability and reduces magnetic leakage by adding inner pole shoes and inner permanent magnets. This improvement increases the magnetomotive force of the magnetic circuit, thereby significantly enhancing the magnetic induction intensity in the sealing gap and the device’s pressure resistance.

4.2 Magnetic fluid sealing devices (Magnetic Feedthroughs) are seals used to prevent gas leakage. They confine magnetic fluid around a rotating shaft to form a liquid “O-ring,” enabling gas sealing.

This type of seal offers long service life, pollution-free operation, high vacuum compatibility, high pressure resistance, and high-speed rotation capabilities. It provides significant advantages in applications such as vacuum sealing for semiconductor manufacturing equipment.

Research indicates that the global market size for magnetic fluid sealing devices was approximately $272 million in 2024 and is expected to reach $384 million by 2031, with a compound annual growth rate (CAGR) of 5.1% from 2025 to 2031.

5 Magnetohydrodynamic Power Generation: A New Approach to Green Energy

5.1 Magnetohydrodynamic (MHD) power generation is a technology that utilizes the motion of an electrically conductive fluid in a magnetic field to generate electricity through electromagnetic induction.

Although MHD generators have been applied in high-temperature molten salt power generation and plasma power generation, large-scale commercialization has not yet been achieved due to limitations in material resistance to high temperatures and corrosion, as well as power generation efficiency.

5.2 Future research and development of MHD generators will focus on overcoming challenges in materials science and engineering design to improve power generation efficiency, extend equipment lifespan, and reduce operational costs.

With the advancement of renewable energy and nuclear power technologies, the potential of MHD power generation in geothermal energy utilization, nuclear waste heat recovery, and solar thermal conversion will be further realized.

5.3 In the rail transportation sector, MHD power generation technology has already made groundbreaking progress. Magnetic Fluid Power (Beijing) Technology Co., Ltd. has developed low-frequency vibration energy harvesting technology that captures vibrations from rail operations and converts them into electrical energy.

The company’s MHD power generation module has operated continuously for over 12,000 hours under simulated heavy-haul railway conditions, with a single module output power stable between 120–300 mW—sufficient to meet the power requirements of most sensors.

6 Future Prospects: The Infinite Possibilities of Magnetic Fluid Technology

6.1 With advancements in materials science and engineering technology, magnetic fluid technology continues to break through existing application boundaries. In the future, we can expect magnetic fluid to play an important role in even more fields.

In the medical field, magnetic fluid could be used for targeted drug delivery and disease diagnosis. In scientific research, Professor Ikezoe of the Tokyo Institute of Technology has developed a technology that uses only four permanent magnets to levitate water at an ultra-low cost. This will make it easy to conduct various experiments on Earth.

The technology is expected to be applied to various sensors such as surface tensiometers, accelerometers, and viscometers, as well as in melting-solidification processes and supercooling experiments.

6.2 As more application scenarios emerge, magnetic fluid technology is expected to bring innovative solutions to various industries.

Shanghai Lingjun Biotechnology Co., Ltd. has long been dedicated to the research, development, production, and sales of products within the biological field. Its primary offerings include magnetic nanomaterials and magnetic bead-based nucleic acid extraction and purification reagents.

Table 1: Magnetic Fluids with Different Particle Sizes from Shanghai LnjnBio

| No. | Product Number | Particle size | Solid content | Specifications |

| 1 | 230061MF | 60 nm | 50 mg/mL | 2 mL、10 mL、50 mL、500 mL、1000 mL |

| 2 | 230062MF | 40nm | 25mg/mL | |

| 3 | 230063MF | 40 nm | 10 mg/mL | |

| 4 | 230065MF | 30 nm | 10 mg/mL |

At present, the company has developed various types of micro and nano magnetic beads, including magnetic fluid (Table 1), monodisperse magnetic beads, polydisperse magnetic beads, silica-based magnetic beads, carboxyl magnetic beads, amino magnetic beads, polystyrene magnetic beads, agarose magnetic beads, streptavidin magnetic beads and so on, and their applications cover the technological fields of nucleic acid extraction and purification, protein purification, cell separation, chemiluminescence and so on.

Supplier

Shanghai Lingjun Biotechnology Co., Ltd. was established in 2016 which is a professional manufacturer of biomagnetic materials and nucleic acid extraction reagents.

We have rich experience in nucleic acid extraction and purification, protein purification, cell separation, chemiluminescence, and other technical fields.

Our products are widely used in many fields, such as medical testing, genetic testing, university research, genetic breeding, and so on. We not only provide products but also can undertake OEM, ODM, and other needs. If you have a related need, please feel free to contact us .