Professional Manufacturer of Biomagnetic Beads

Efficient Wastewater Treatment Using Silica-Based Magnetic Beads

Greetings, individuals passionate about the environment and experts in the water treatment sector! In today’s discussion, we’ll set aside fantastical elements and delve into the realm of scientific advancements. One such innovation leading the charge in wastewater treatment is the utilization of silica-based magnetic beads, which effectively coax wastewater into compliance. Despite their futuristic title, these beads serve as exceptional assets in enhancing wastewater treatment processes.

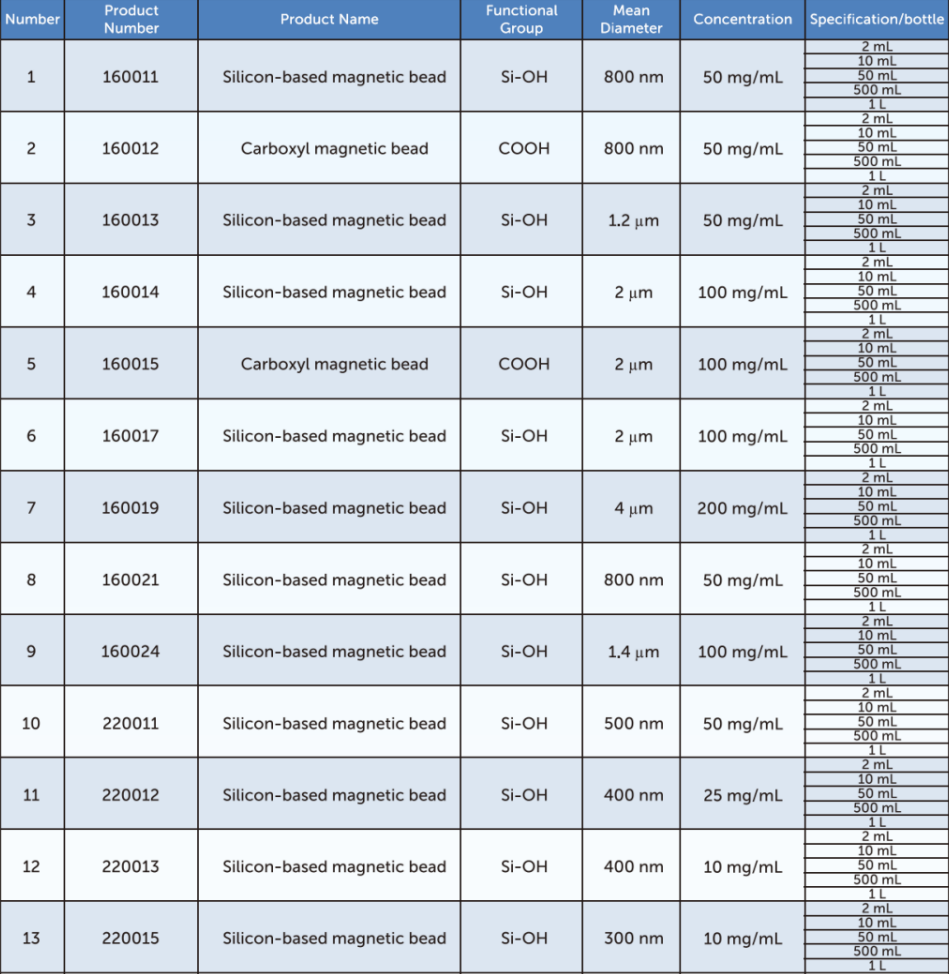

1. What Are Silica-Based Magnetic Beads?

In simple terms, they are nanoscale spheres with a magnetic core (composed of Fe₃O₄) and a silica shell (SiO₂). Their diameter is approximately one-hundredth of a human hair, yet their ability to adsorb pollutants rivals that of a sponge soaking up water!

2. How Do They Work? Three Steps to Treat Wastewater!

Release: Introduce the silica-based magnetic particles into the wastewater, where they will rapidly converge on and bind to contaminants such as heavy metals (like lead and chromium), organic pollutants (including dyes and pesticides), and oil, much like predators tracking down their quarry.

Capture: Functional groups (e.g., -NH₂, -COOH) on the silica surface securely bind pollutants through electrostatic adsorption or chemical bonding.

Extraction: Use a magnet to attract the magnetic beads—within 10 seconds, the magnetic beads, along with the adsorbed pollutants, are completely removed, leaving the water instantly clear!

Data-Driven Facts:

Adsorption capacity of up to 300 mg/g (twice that of activated carbon!).

Separation time <5 minutes, compared to over 2 hours for traditional sedimentation.

Reusable for ≥10 cycles, reducing costs by 60%.

3. Why Choose Them? Advantages That Outperform Conventional Methods!

| Aspect | Silica-Based Magnetic Beads | Activated Carbon/Resins |

| Efficiency | Rapid adsorption & separation; tackles challenging wastewater | Slow and selective |

| Cost | Reusable ≥10 times | Typically single-use, continuously draining funds |

| Eco-Friendliness | Reduces sludge by 70%; allows heavy metal recovery & recycling | High risk of secondary pollution |

| Operation | Fully automatable | Relies on manual labor, exhausting engineers |

4. Real-World Case: The Electroplating Plant Turnaround!

A certain electroplating plant faced severe nickel ion (Ni²⁺) issues. After treatment with silica-based magnetic beads:

Removal rate > 95%

Recovered nickel metal for resale (saving $ 702,000 annually!)

The rate of wastewater recycling rose by 40%.

5. Conclusion: Silica-Based Magnetic Beads—The Future of Water Treatment!

This innovative technology serves as a prime example of the circular economy by addressing pollution, reclaiming resources, and reducing expenses.

Comparatively, in the realm of wastewater treatment, silica-based magnetic beads act like a targeted precision weapon aimed at contaminants, akin to a magnetic laser gun.

If you’re intrigued, please don’t hesitate to reach out! Let’s collaborate to enhance the purity of water and promote environmental sustainability.

Place your order now—don’t hesitate!

Supplier

Shanghai Lingjun Biotechnology Co., Ltd. was established in 2016 which is a professional manufacturer of biomagnetic materials and nucleic acid extraction reagents.

We have rich experience in nucleic acid extraction and purification, protein purification, cell separation, chemiluminescence, and other technical fields.

Our products are widely used in many fields, such as medical testing, genetic testing, university research, genetic breeding, and so on. We not only provide products but also can undertake OEM, ODM, and other needs. If you have a related need, please feel free to contact us .