Professional Manufacturer of Biomagnetic Beads

Silica-Based Magnetic Beads for Treating Zinc Plating Wastewater

Dear zinc plating factory owners, engineers, Does wastewater treatment trouble you? Excessive zinc and nickel content, mountains of sludge, environmental fines looming… Don’t worry! Today, we’re recommending a truly powerful and cost-effective cutting-edge technology—the Silica-Based Magnetic Beads Wastewater Treatment Solution!

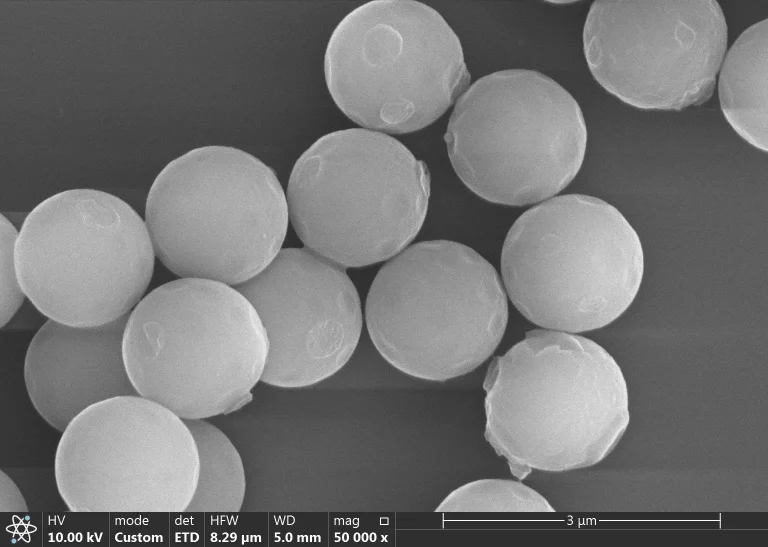

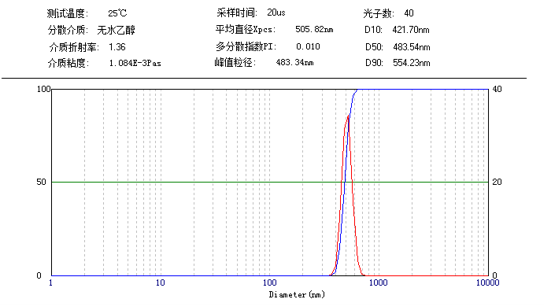

What are silica-based magnetic beads? We’ve already introduced them in a previous article, so we won’t go into too much detail here. Just remember: although these beads are only 1/100th the diameter of a human hair, their adsorption capacity is comparable to a vacuum cleaner!

1. Three Major Points in Zinc Plating Wastewater Treatment & Magnetic Bead Solutions

Point 1): Excessive Zinc (Zn²⁺) and Nickel (Ni²⁺) content, High Sludge Volume and Cost with Traditional Chemical Methods

Magnetic Bead Solution:

- Add amino-modified magnetic beads (-NH₂ specifically captures zinc and nickel ions)

- Magnetic separation (solid-liquid separation in 5 minutes)

- Acid washing regeneration (recover metal resources, recycle beads)

Data :

Zn²⁺/Ni²⁺ removal rate > 98%

Sludge volume reduced by 70%

Annual metal recovery revenue up to $56,240 per 10,000 tons of water

Point 2): Complex Wastewater Composition, Poor Adaptability of Traditional Processes

Magnetic Bead Solution:

- Precisely targeted adsorption by functionalized beads, strong anti-interference capability

- Wide pH applicability range (3-10)

Advantage:

No frequent pH adjustments, saving chemicals and labor

Point 3): Long Treatment Process and Large Footprint

Magnetic Bead Solution:

- Integrated magnetic separation equipment, reducing footprint by 50%

- Fully automated process, no need for dedicated monitoring

Efficiency Comparison:

Traditional sedimentation takes 2-4 hours → Magnetic separation takes only 5 minutes!

2. Technical Mechanism: How Do Magnetic Beads “Catch Zinc and Trap Nickel”?

- Electrostatic Adsorption: Surface -NH₂ groups are charged, strongly capturing Zn²⁺ and Ni²⁺

- Chemical Complexation: Functional groups form stable bonds with metal ions (more stable than ion resins!)

- Magnetic Recovery: External magnetic field rapidly collects beads in 10 seconds, wastewater becomes clear instantly!

- Regeneration Cycle: Elution with dilute HCl (0.1M), beads reused ≥10 times with >85% capacity retention!

3. Cost Analysis: Is It Really More Cost-Effective Than Traditional Methods?

Take daily treatment of 1,000 tons of wastewater as an example:

| Item | TraditionalChemicalPrecipitation | Silica-BasedMagneticBeadProcess |

| Chemical Cost | $0.84-1.69/ton water | $0.42-0.7/ton water (acid regeneration) |

| Sludge Disposal Cost | $0.7-1.12/ton water | $0.14-0.28/ton water (70% reduction) |

| Labor & Maintenance | $0.56-0.84/ton water | $0.14-0.28/ton water (automation) |

| Total Cost | $2.39-3.66/ton water | $0.7-1.12/ton water |

Conclusion: Magnetic bead solution saves >60% in costs and even generates revenue from recovery!

Worry-Free, Effort-Free, Cost-Eaving. Heavy Metal Removal Rate > 95%!

Let magnetic technology help you save money, save effort, and pass environmental reviews with ease!

Place your order now—don’t hesitate!

Supplier

Shanghai Lingjun Biotechnology Co., Ltd. was established in 2016 which is a professional manufacturer of biomagnetic materials and nucleic acid extraction reagents.

We have rich experience in nucleic acid extraction and purification, protein purification, cell separation, chemiluminescence, and other technical fields.

Our products are widely used in many fields, such as medical testing, genetic testing, university research, genetic breeding, and so on. We not only provide products but also can undertake OEM, ODM, and other needs. If you have a related need, please feel free to contact us .